About

Founders of high effective heat exchangers

In 1992 Level energy technology developed a counterflow heat exchanger and obtained patents on both the geometry and the production method. The counterflow recuperator was a significant improvement on the then commonly used cross flow heat exchangers. In 1999 production of the plastic counterflow heat exchanger started. These recuperators are mainly used in centralised heat recovery units in residential buildings. Level is the founder of heat recovery from ventilation air with high efficiency (>90%). Among others Storkair, Itho and Stiebel Eltron were the first manufacturers to launch a HRV-unit based on the Level heat exchanger.

Since 2002 Recair in Waalwijk manufactured the recuperators according to our patents. The first type of heat exchanger, the HR160, has been produced and sold over 160.000 times. In 2005 Level acquired Recair (together with it's management) from Zehnder to become an independent supplier. Level was responsible for innovation and development.

In 2006 Peter Hoogendoorn (Level) developed a greatly improved geometry, the RS160. In total >1.000.000 heat exchangers have been manufactured according to Level patents. Other manufacturers started producing heat exchangers with the same outer shape. All the currently available plastic heat exchangers are produced by thermoforming, a succesful and reliable production method.

In 2017 Level developed the next generation heat exchanger. Using innovative production techniques, an improved and more robust heat exchanger can be produced. Patents have been obtained on both geometry and production technology. The next level

heat exchanger is characterised by a higher quality in performance, effectiveness and pressure drop as well as in firmness, robustness and size accuracy. Level produces the Next Level

heat exchangers in its own production facility.

Other projects

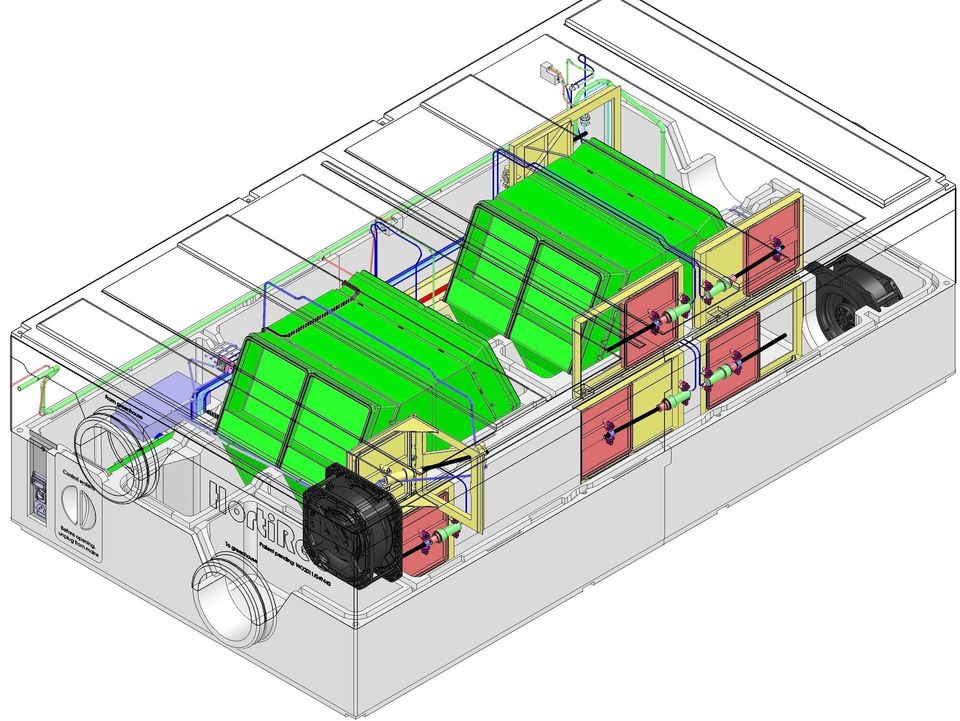

Hortirec

The HortiRec system has been designed to give horticulturists the ability to control and maintain the desired humidity, temperature and CO₂ level in their greenhouses, without having to open the windows in the greenhouse. By making use of heat and moisture recovery energy consumption is reduced to a minimum. The CO₂ level in the greenhouse can be kept high without CO₂ leaving the greenhouse via the windows. The system makes it possible to maintain a constant high growth climate.

The modular HortiRec system can also be applied in semi-closed greenhouses: only at peak loads the windows have to be openend.

In addition to the energy and CO₂ savings the HortiRec system gives increased opportunity to control the climate for the horticulturist. As the temperature, humidity and CO₂ levels can be set accurately and distributed homogeneously a greater influence on the growth of the crop is obtained. Not only does this account for increassed production, but also leads to a better quality of the product.

Smartbox

Smartbox

Level developed and patented a new heating, ventilation and air conditioning system, called the ‘Smartbox’. The Smartbox combines ventilation, heating, cooling and (de)humidification for a standard office. It ensures a comfortable and healthy indoor climate and delivers fresh air at a temperature, humidity and flow rate that fits the needs of the individual user.

Sensible and latent heat (moisture) are recuperated in the enthalpy exchanger with an effectiveness of > 92%. Cooling and heating is controlled by a heat pump.

The system COP is > 10, depending on the conditions. The unit is positioned above the window on the ceiling between two floors. Only supply of electrical energy and a removal of condensate is necessary.

The Smartbox is not currently in production. Several prototypes have been produced to validate proof of principle

Patents

In 1994 Level obtained their first patent for the geometry of counterflow heat exchangers, followed by other patents for both geometry and production method. Since 1998 a couple of heat exchanger types have been produced according to the Level patents.

Beside developing heat exchangers, Level also developed systems utilizing heat exchangers. Hereby obtaining several patents such as an enthalpy heat exchanger, the Smartbox and the HortiRec.

After 2013 several new patents on internal geometry and production methods of counterflow heat exchangers were obtained. The next level

heat exchanger is of course produced according to the latest technology developed by Level. Resulting in the best recuperator on the market.